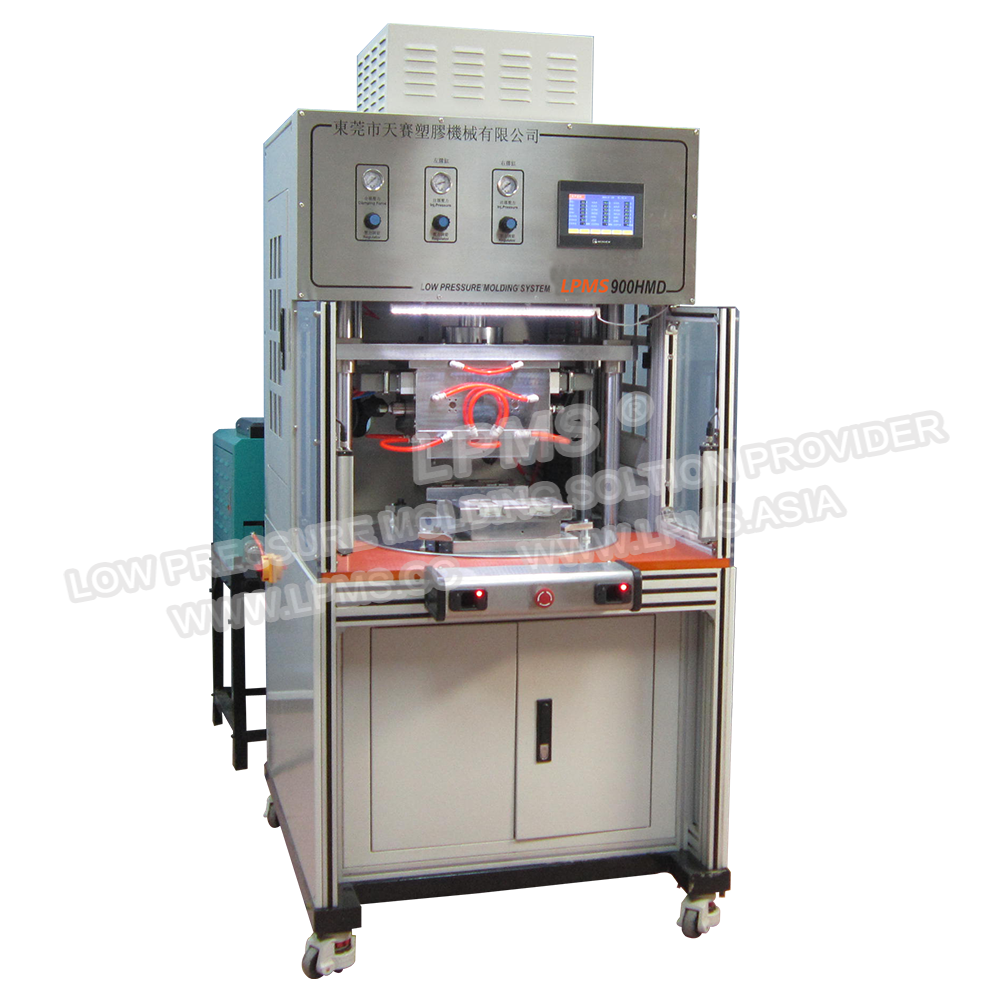

One upper mold handles two bottom molds on turntable less mold cost and high productivity.

Equipped with latest LPMS gear pump, machine is compact and reliable.

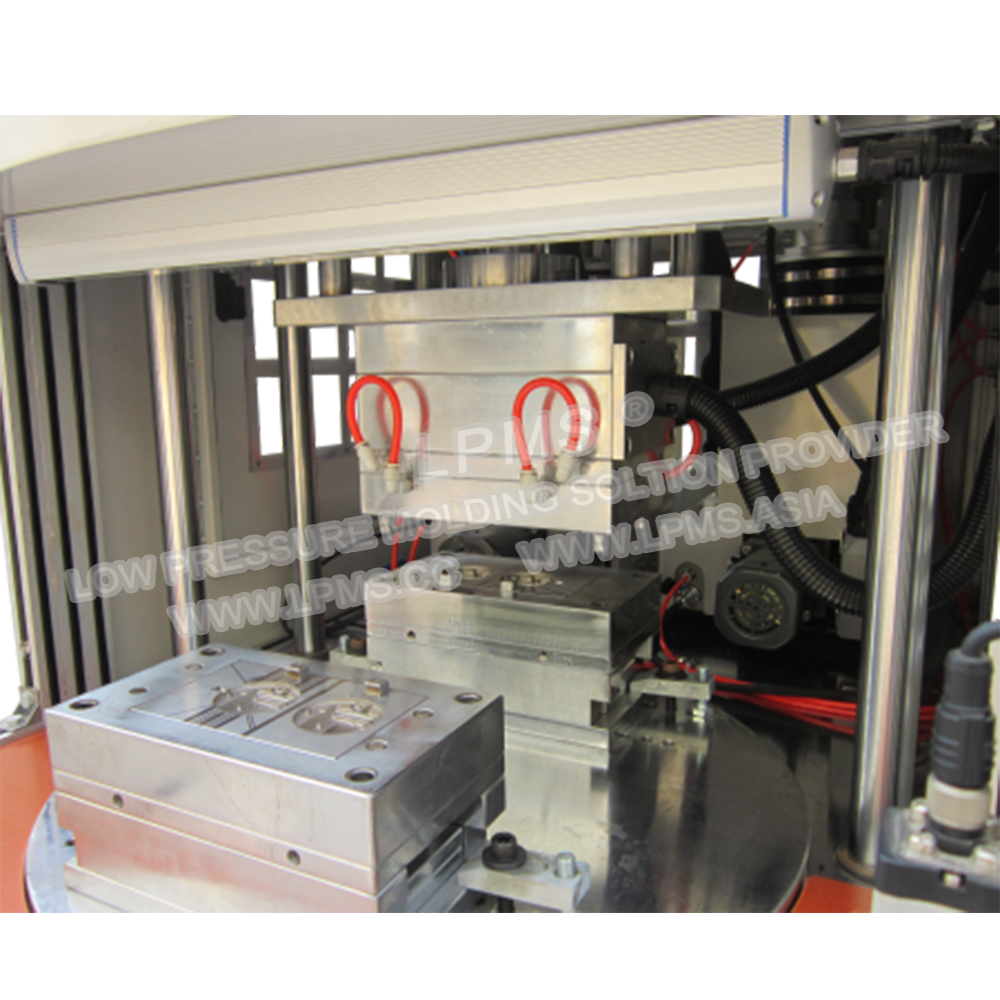

Hot-Runner system, Hot nozzles are located on top of product,injection time is shorter,resin is saved and appearance quality is better

Injection applications position are adjustable for fitting different battery sizes. More flexible.

Air-Over-Oil cylinder provide more clamping force and speed for clamping. It meets the requirement of large size Lithium Polymer batteries for larger resin weight.

Precise injection pressure can be regulated on operation panel.

Individual temperature control at tank, tube, and injection applicators.

Machine equipped with dual melters tanks for big shot size product and remains the production stabile.

Dual-Palm-Actuated, Extreme Safety Light Curtain and Safety Door to keep operator in safe during operation.

Machines are equipped with ejection system; parts are Easily removed after molding. Mold sets can be easily changed in a few moments.

Application

LPMS? machines are engineered for low pressure molding, using specialty resins to encapsulate delicate parts, like automotive electronics, PCBA, coil, fiber-optic, LED lighting, cable, etc.

The benefits of vertical injection is that when smaller parts allow the cavity to be split into two or four cavities. This allows shorter runners and higher output per cycle. It’s suitable for multiple cavity mold for cable, wire harness, LED, etc.

Applications span many industries including: Automotive, PCBA,Coil,Fiber-Optiv,LED Lighting, Wire and Cable,and Electronics

Specification

Machine Size / Weight | 1020x1200x2010mm/450Kg 40.16×47.24×79.13in/992lbs |

Working Station Height | 855mm 33.66in |

Packing Size / Weight | 1150×1300×2100mm/500Kg 45.28×51.18×82.68in/1102lbs |

Melting Tank | LPMS MT05-900HMD x2 |

Maximum shot size | 5.8g / RPM |

Auto Feeding System | Optional |

Gun Model & Tip | Hot Runner System |

Each Station Gun Tip Qty | 2 or 4 depends on part design |

Gun Y direction adjusting range | 50--100mm |

Heated Hose | LPMS-TH16Jx2 |

Electricity | 200-240VAC/50or60Hz |

Temperature Control Zones | 10 or 12 according to the part |

Temperature Range | Ambient up to 250°C / 485°F |

Max. Power | 11Kw |

Pump Motor | 120 W |

Min. Air Pressure | 0.5MPa | 73 Psi |

Air Consumption | 0.1m3/min |

Clamping | Air Over Oil Cylinder |

Clamping Force | Max.5 Tons ( Optional 10 Tons ) |

Clamping Stroke | 75mm | 2.95 in |

Mold opening force | 350 Kg / 772 lbs |

Ejector | Air Cylinder |

Ejector Force | 980 N |

Ejector Stroke | 10 mm | 0.39 in |

Safety Protection | Light Curtain, emergency stop button and Safety door |

Control System | 7 ”HMI , PLC controlled |

Mold Set Size | 300 mm x 260 mm x 390mm 11.81 in x 10.24 in x 15.35 in Please Refer to Mold set dimension below |

Max . Part Size | 100 mm x 90 mm x 18 mm 3.94 in x 3.54 in x 0.71 in |

Dimension

Video

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.